MES Software

In a factory, all kinds of goods are created. When you look at a factory up-close, it can (often) be simplified to a bunch of machines doing fairly simple operations, and many operators ensuring the productiveness of the machine. Looking at it from a distance reveals a different story, one of supply, and demand. The factory receives all kinds of orders from customers, and outputs all kinds of products which fulfill these orders.

When talking about the up-close details of the factory, the machines, the software-side of the story is often about PLC’s and HMI’s. There are entire industries built around PLC’s and their programming. An example of this is Siemens, with their S7-series and TIA Portal. The software-side of the larger picture is often about ERP software, examples of this are SAP, or Microsoft Navision. This blog-post is about the glue that combines both worlds, also known as Manufacturing Execution Systems (MES) or Manufacturing operations management systems (MOMS).

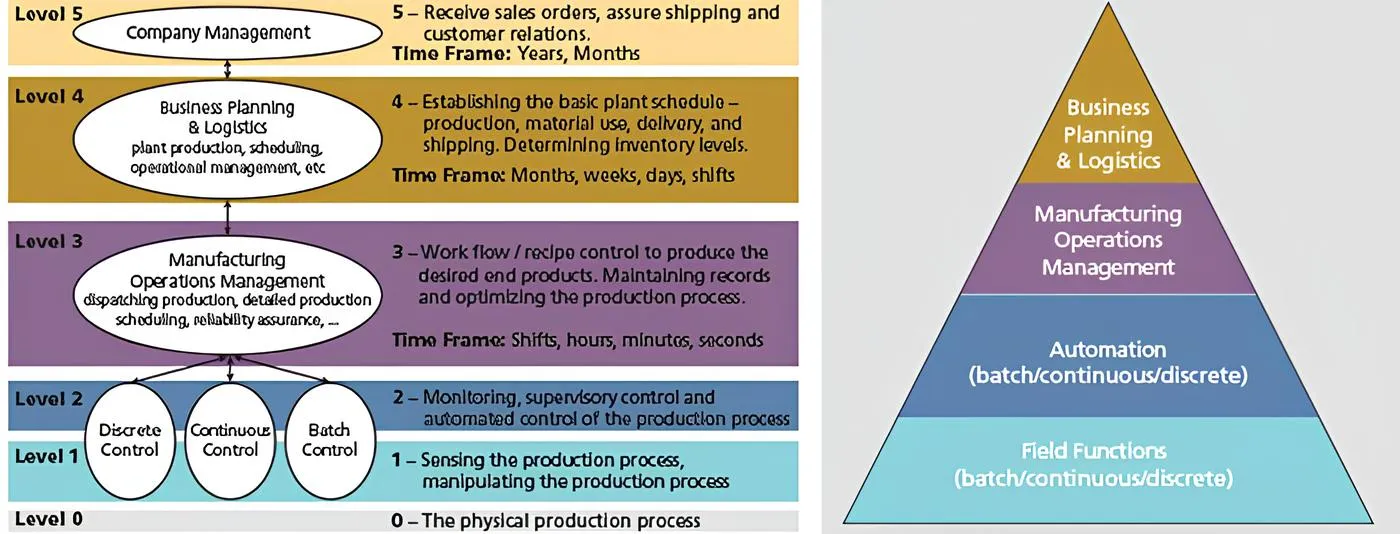

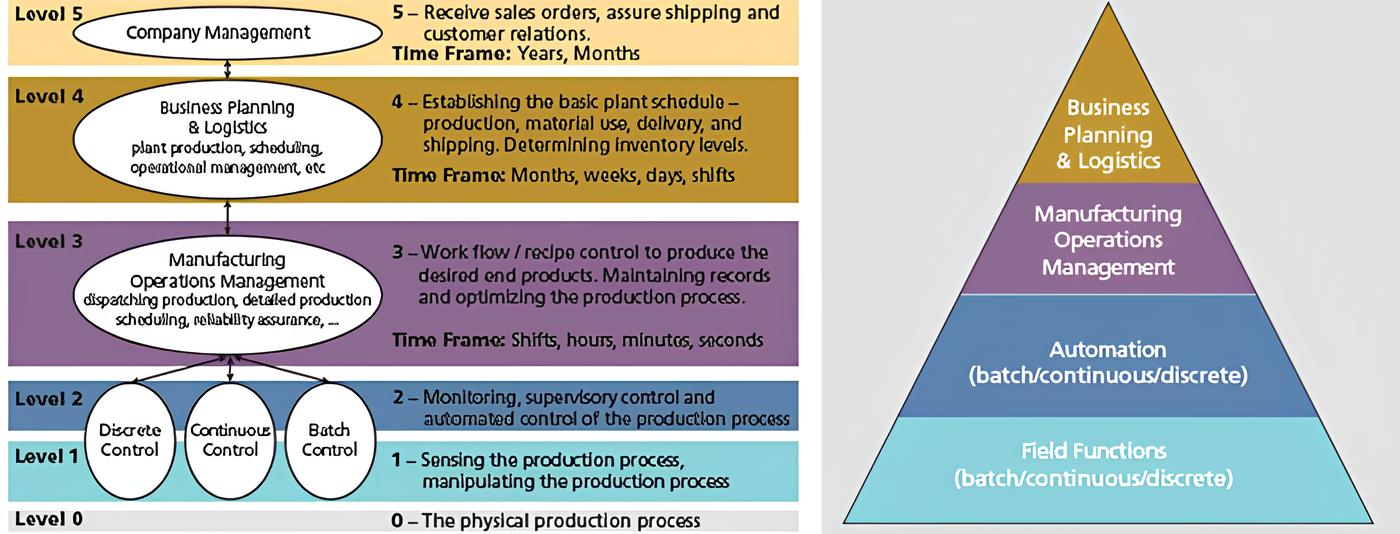

One international that defines most of the terminology used in MES software today is ISA-95. ISA-95 defines the following ‘levels’ of the manufacturing process:

There are several ISA-95 parts, all of which define different parts of the entire standard. The first two parts describe the different models, their terminology, and the way data flows between them.

How a manufacturing environment is defined

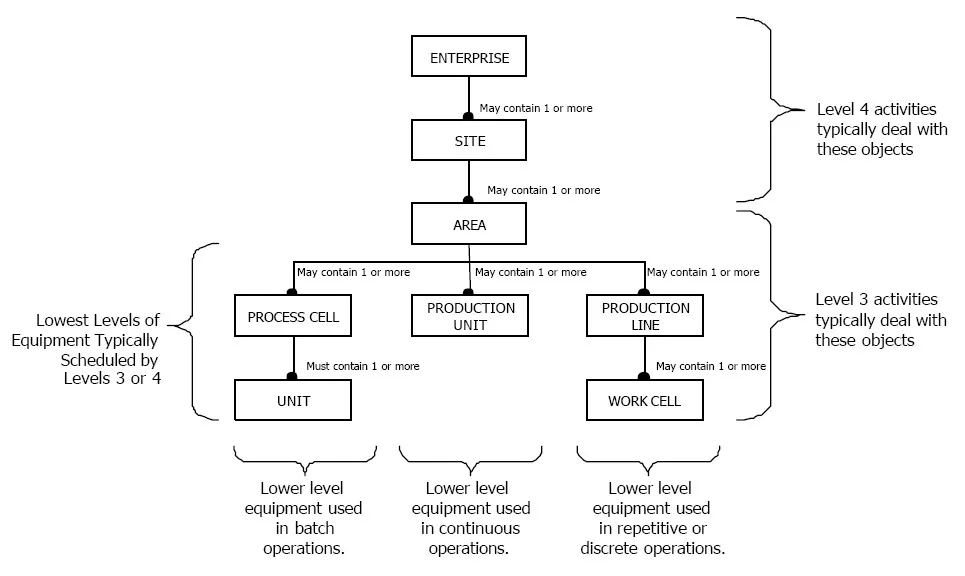

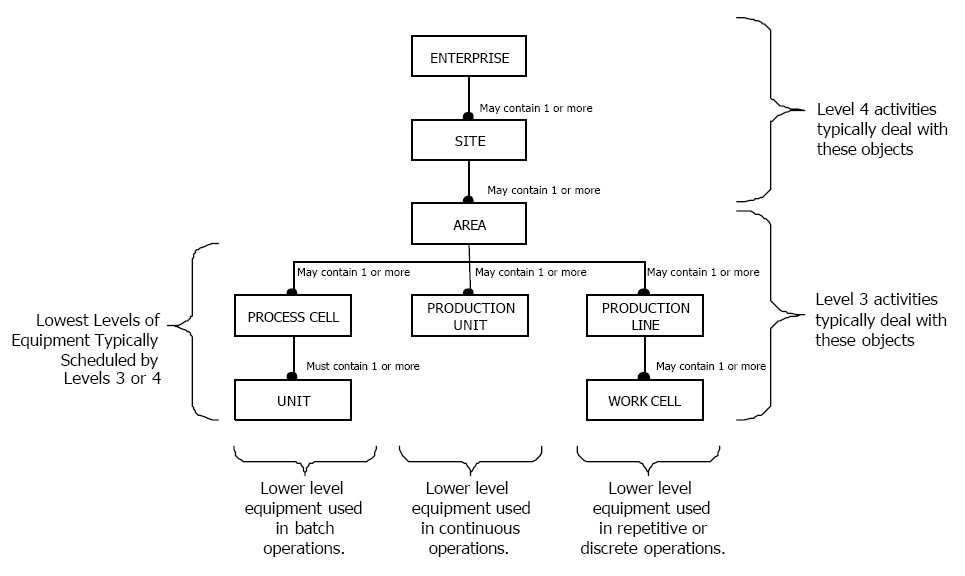

A company can be defined in a hierarchical sense. The same goes for a factory. A factory may have many different processes, all of which happen in a segment defined in the following diagram:

For HolyMate, we have the following processes:

- Boiling water

- Steeping the tea

- Mixing different ingredients

- Filtering the tea

- Preparing the tea for storage in a soda keg

- Labelling the keg

All of the above processes would be defined as a level-3 activity. All processes (except labelling!), as we currently execute them, are batch processes. Which means that we are mostly dealing with process cells, all of which are contained in the area known as Hackalot’s kitchen.

ISA-95 also defines a way to store these models. In a future blog post, I will explore these models and implement parts of the ISA-95 standard in C#. My ultimate goal is management of the HolyMate production process, where each glass served has complete traceability.